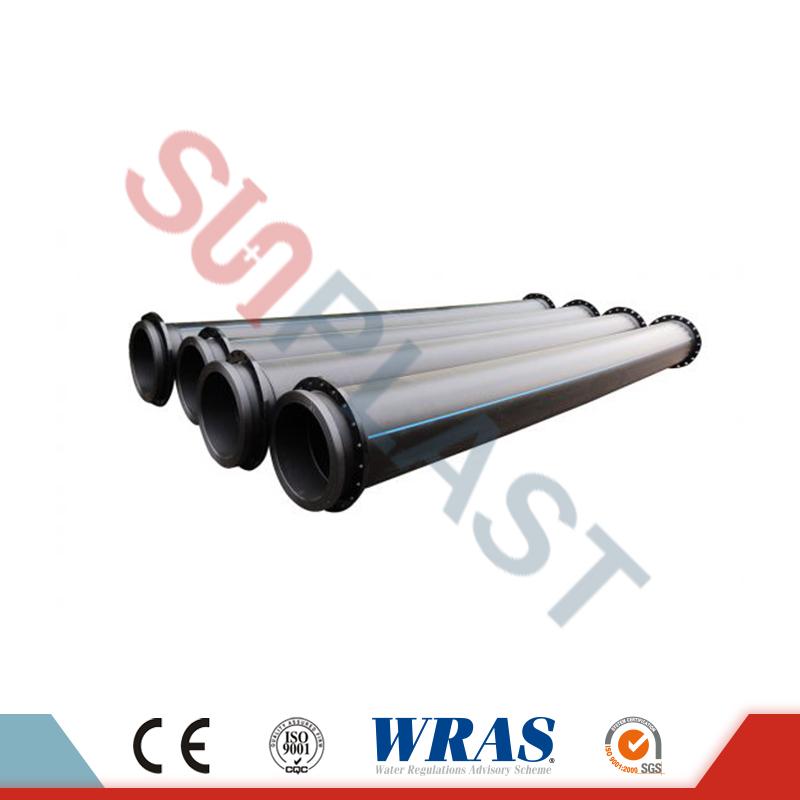

HDPE Dredge Pipe

High-Density Polyethylene (HDPE) dredge pipes are specialized plastic pipes designed for use in dredging and marine construction applications. These pipes are engineered to withstand the challenging conditions encountered in dredging operations, where they are used to transport sediment, slurry, and......

Send Inquiry

Product Description

High-Density Polyethylene (HDPE) dredge pipes are specialized plastic pipes designed for use in dredging and marine construction applications. These pipes are engineered to withstand the challenging conditions encountered in dredging operations, where they are used to transport sediment, slurry, and other materials. Here are some key characteristics and applications of HDPE dredge pipes:

1. Material: HDPE is a thermoplastic material known for its high strength, durability, and resistance to corrosion, making it suitable for marine and dredging environments.

2. Lightweight: HDPE dredge pipes are lightweight compared to traditional steel or concrete pipes, which makes them easier to transport, handle, and install.

3. Flexibility: HDPE pipes have a high degree of flexibility, allowing them to bend and adapt to the contours of the seabed or riverbed. This flexibility is important for navigating underwater obstacles.

4. Abrasion Resistance: These pipes are designed to withstand abrasion from the movement of sediment, rocks, and other materials transported during dredging.

5. Corrosion Resistance: HDPE is naturally resistant to corrosion, which is crucial in marine and water environments.

6. Smooth Interior Surface: HDPE dredge pipes have a smooth inner surface that minimizes friction and prevents clogs or blockages in the pipeline.

7. Durability: HDPE pipes have a long service life and are resistant to degradation from exposure to sunlight, chemicals, and marine environments.

8. Connection Methods: HDPE dredge pipes are often joined using heat fusion or butt welding techniques, creating strong, leak-free connections.

9. Floatability: Some HDPE dredge pipes are designed with floatation collars or floats to keep them buoyant in water, making them easier to install and maintain.

HDPE dredge pipes are used in a variety of marine and dredging applications, including:

1. Dredging Operations: These pipes are essential for transporting sediments and slurry during dredging projects, such as harbor deepening, channel maintenance, and land reclamation.

2. Offshore Mining: In offshore mining operations, HDPE dredge pipes are used to transport materials like sand, gravel, and minerals from the seabed.

3. Environmental Remediation: HDPE dredge pipes are used in environmental cleanup projects, such as removing contaminated sediments from water bodies.

4. Agricultural and Irrigation Dredging: In agricultural and irrigation applications, these pipes help maintain drainage and irrigation channels, preventing waterlogging and flooding.

5. Aquaculture: In aquaculture settings, HDPE dredge pipes are used for water intake and discharge, as well as in recirculating aquaculture systems.

Proper installation and maintenance of HDPE dredge pipes are crucial to ensuring the efficiency and longevity of dredging and marine construction projects. The selection of the appropriate diameter and wall thickness is based on the specific project requirements, including the material being transported, the distance, and the depth of the dredging operation. Additionally, adherence to safety and environmental regulations is essential in marine and dredging applications.